But, let’s say you’re still focusing on OEE, and you find it is increasing. One of the most important parts about understanding what to do once you’ve increased OEE is establishing – in a credible fashion – that you actually have increased it. Duh, right? Not so fast. There are a lot of manufacturers out there that think they are reliably collecting machine data, but the data is neither accurate nor consistent.

Step 1 in determining if you are working from a consistent number should start by asking yourself, “How do I know for sure my data is right?” If you aren’t confident in your answer, consider what could be done about it. Tools like Mingo make it very easy to view all of your machine data.

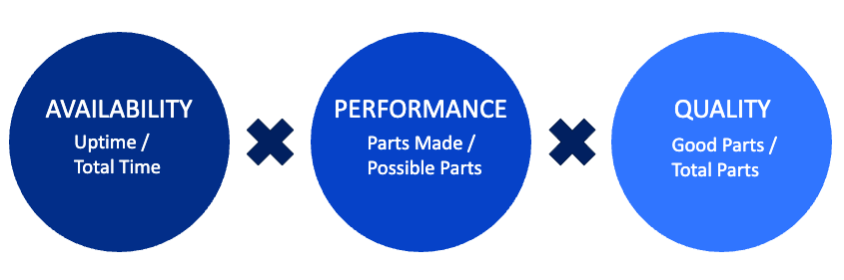

Once you can confirm the reliability of the data, you can identify key metrics that you can benchmark and measure against. This is the whole point of OEE. It’s the ability to establish an efficiency metric and see if the initiatives you put in place or improvements you make in processes can improve those things (but, OEE can be flawed, so be careful). If your data is good, you can usually identify issues and do something to improve them.