1. How much money am I losing by not running these machines?

2. Am I producing to capacity?

3. What are underproduction and downtime really costing my manufacturing business?

These are questions that even the best manufacturers should constantly be asking themselves. In the name of continuous improvement, these questions should permeate the walls of your shop floor like a metronome. Why? Because improving upon these answers can save you a lot of money!

Who doesn’t want to save more money? That’s right, there isn’t a manufacturer in the world who doesn’t want to save money.

What’s the difference between a dollar spent and a dollar saved? In this case, the opportunity to impact the bottom line through savings is much greater… let me explain.

Manufacturers Find Out About Underproduction and Downtime Too Late

One of the biggest issues with how manufacturers learn about their challenges with downtime and underproduction is that they learn about it after it has already cost them a lot of money, an expensive lesson to learn.

Changes and issues are handled retroactively, meaning that solutions often come too late for real savings to take place. It’s like taking your car in for routine maintenance after it’s out of oil and the engine is blown out. Think of the vast consequences that would ensue if your engine is beyond repair, yet you’re still expecting your car to work the next time you want to go for a drive.

I’ve worked with a lot of manufacturers, and most don’t know how much of an impact underproduction or downtime has cost them until the end of the year or the end of the quarter.

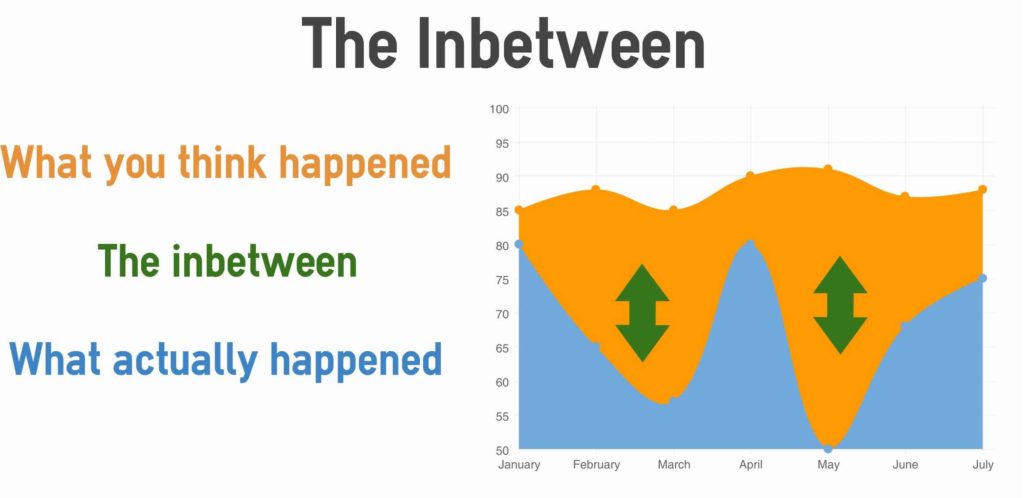

They see that they lost money vs. what they should have made or projected to make, but really struggle to understand exactly why. I talked about this idea a little bit before when discussing scrap rates. Many wonder if there is a better way to operate or a solution to their problems.

It’s Hard to Figure Out What Went Wrong 3 Weeks Ago….

Outside of being downright costly, the reason why finding out about underproduction or downtime months after it’s happened can be damaging is because it is really hard to go back that far and dig deep enough to discover the root cause of the expense. This means that the mistakes that cost you a lot of money before, are likely to do it again, at some point — or even worse — they are a chronic part of shop floor practices.

This process will likely become a revolving circle, continuously happening with no end in sight because there is no visibility into the floor.

I’ve spoken candidly with a lot of executives inside of these manufacturing companies; they admit that when they get to the end of the year, they know they made money because they know that they had more profit than expenses, but they don’t know what product mix that produced that profit.

If you’ve done well, how do you make that a repeatable process without knowing why?

Understand Why with a Manufacturing Example

Here’s an analogy that one anonymous Manufacturing CEO gave me about this:

• Blue coffee cup produces $10 in profit

• Black coffee cup produces $9.65 in profit

• Red coffee cup produces $5.00 in profit

• Green Coffee cup produces no profit (and actually costs the business $0.65)

Standards for these coffee cups may all be the same, but the reality is that they are all being made at different rates, have varying downtime in the production cycle, and have different scraps rates.

All of these things contribute to profitability and if you do not understand how these things are impacting each product, you may not know where your profit is coming from.

In this example, it’s obvious the blue coffee cup is being produced fairly well (at least comparatively), but there are major issues with the green one. This CEO believed that many manufacturers lack the ability to identify this issue (meaning most would not even know the differences between green and blue).

You Have to Know the Difference and You Have to Know Why!

Setting aside the fact that most people reading this recognize the importance of knowing the profitability of their different products, I would argue adamantly that manufacturers have to understand why these things happen to truly save money.

The downtime itself can be associated with things like scrap or maintenance. Perhaps all issues are due to overheating or labor changes, which may be a fixed part of the production, but if you can’t understand why these things occurred (long breaks by the night team, the temperature gets too high on machine B due to bad parts, etc.) you’ll never be able to save money.

And… if you want to know why it is much easier if you can see these issues as they happen. Finding out 3 months down the road only further contributes to this problem and allows for the waters to be muddied by a number of competing caveats.

Calculating the Loses can be Eye-Opening

If it costs you $80 an hour to run a machine, labor, downtime, etc. You lose $80 an hour when it’s not producing properly (or it’s not running at all).

It’s intuitive – you know you’re losing money, but it’s usually more than what people think. However, this is the most innocuous example. Most people inherently know this is happening to some degree.

The real silent killer is…

If a machine should produce 10 parts a minute but instead it’s only producing 9 then you have to run the machine X minutes longer to get the same production out of it. This time is worth money as well.

Manufacturers usually have enough of a feel for the cost of downtime to keep machines running enough to prevent gut-wrenching losses, but this kind of underproduction can create costly slow bleeding effects for years.

What’s more, this form of waste could end up costing you more over the long haul because you are aware when a machine is not running but you are not aware of the cost of a machine underproducing.

In my opinion, this is the ROI argument for the benefits manufacturing analytics can provide.

There’s a simple ROI calculator that can prove that argument.

X Hours Needed to Improve vs. Cost of Manufacturing Analytics

Manufacturers Can Get By With Little Data

A lot of times these ideas look good on paper but get convoluted in reality: too many Excel spreadsheets, too little cohesion between the back office and employees on the floor, the reasons can go on and on.

The truth is that it is okay to simplify. There’s an argument that can be made for getting rid of pen and paper and Excel and resolve to track a single data point that can help you understand why underproduction and downtime occur. Then, with that understanding, take the steps to improve. Little data can be better than big data.

In most cases, I’ve found that a handful of simple dashboards on manufacturing analytics software can save manufacturers a lot of money.