- Product

- Solutions

Case Studies

Automation

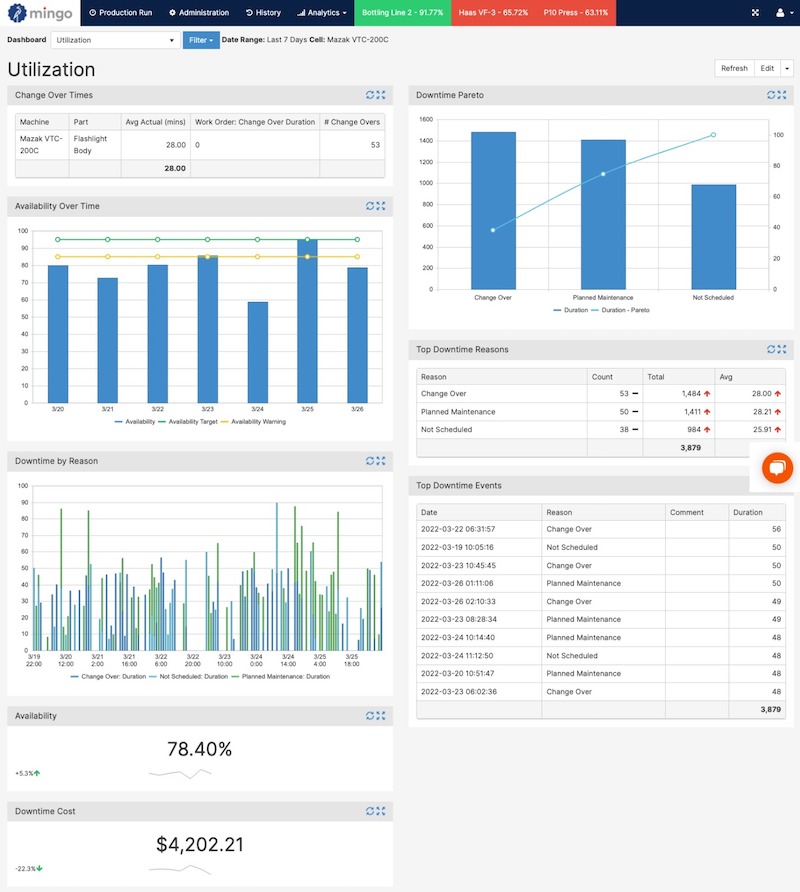

Versatech Increased OEE 30%Consumer Package Goods

Oral Biotech Eliminated ScrapFurniture

Tacony Reduced Lead Time 150%Metal Stamping

H&T Waterbury Reduced Downtime 71%Blow Molding

Lyons Blow Molding Automated Reporting & Labeling - Resources

- Blog