Versatech CEO, Chad Hill, believed that by giving quality, engineering, maintenance, production, and other departments real-time data, they could enhance the efficiency of their operations. Specifically, they could improve the ability to reduce overtime, decrease downtime, and improve machine utilization.

“We wanted to get the data into one location and have a single-tracking system that looked at data in real-time,” said Hill.

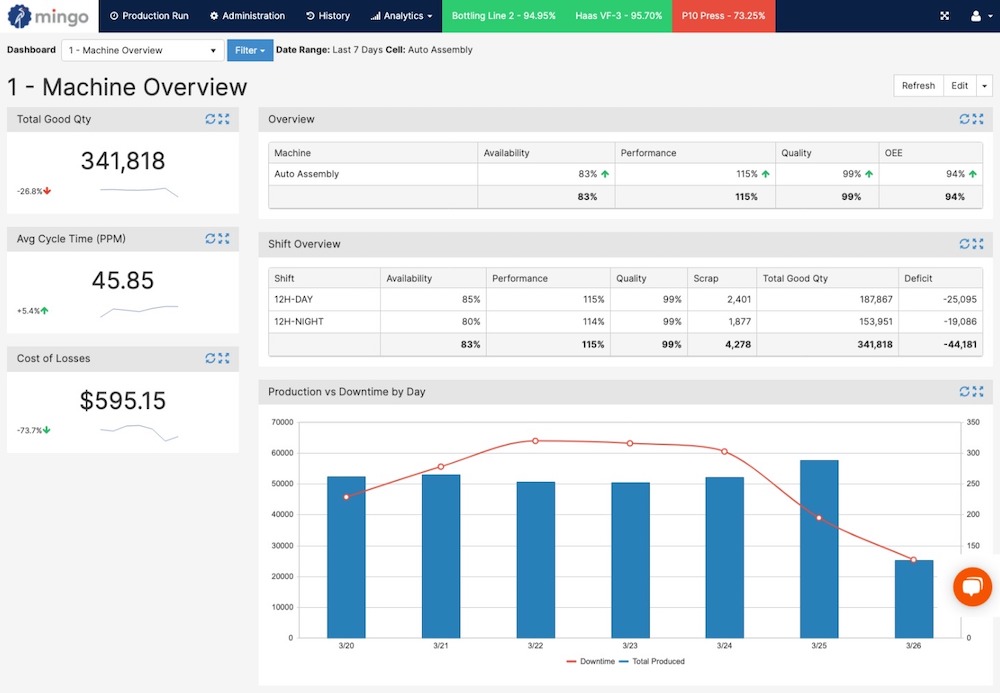

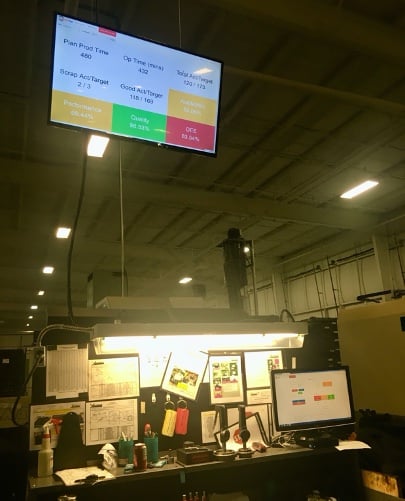

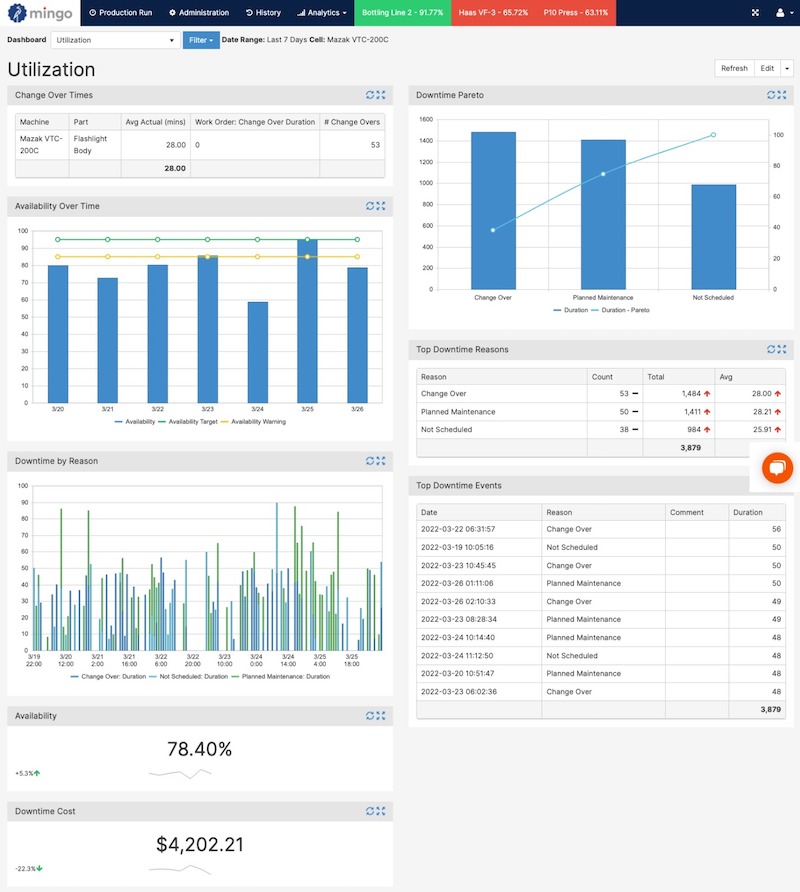

According to Hill, Mingo offered both contextual and real-time opportunities to access insights out of the central database, including the ability to start auto collecting data to display automatically in dashboards across the organization.

Often, manufacturing software implementations and cross-department adoption can take a long time, and failure rates are often above 50%. That wasn’t the case with Mingo.

One of the most significant benefits of Mingo is that it doesn’t require lengthy implementation or complex integration. Despite a few internal staffing changes, Mingo was successfully implemented across the organization and producing measurable results in less than 3 months.

Hill believes that any manufacturer could implement, adopt, and start achieving ROI in less than 3 months, just as Versatech did, using the application and the insights that manufacturers can pull out of it.

“The process was really very easy. There’s no reason why anyone couldn’t do it (implement Mingo) and start getting good results in 3 months”, Hill shared.

“Mingo is so much easier to use… it is almost dummy-proof.”