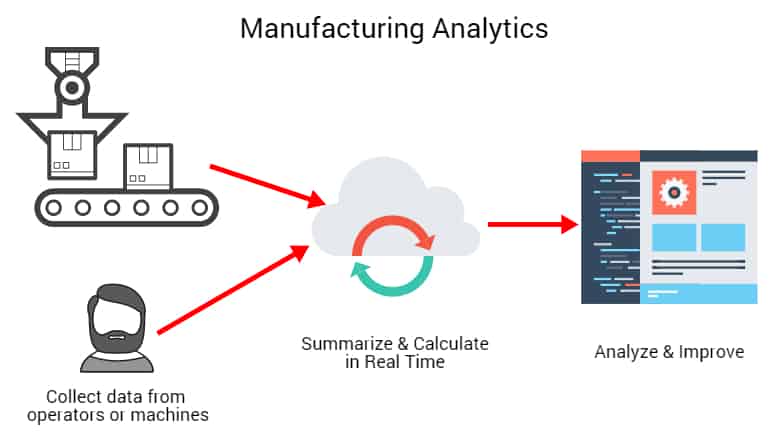

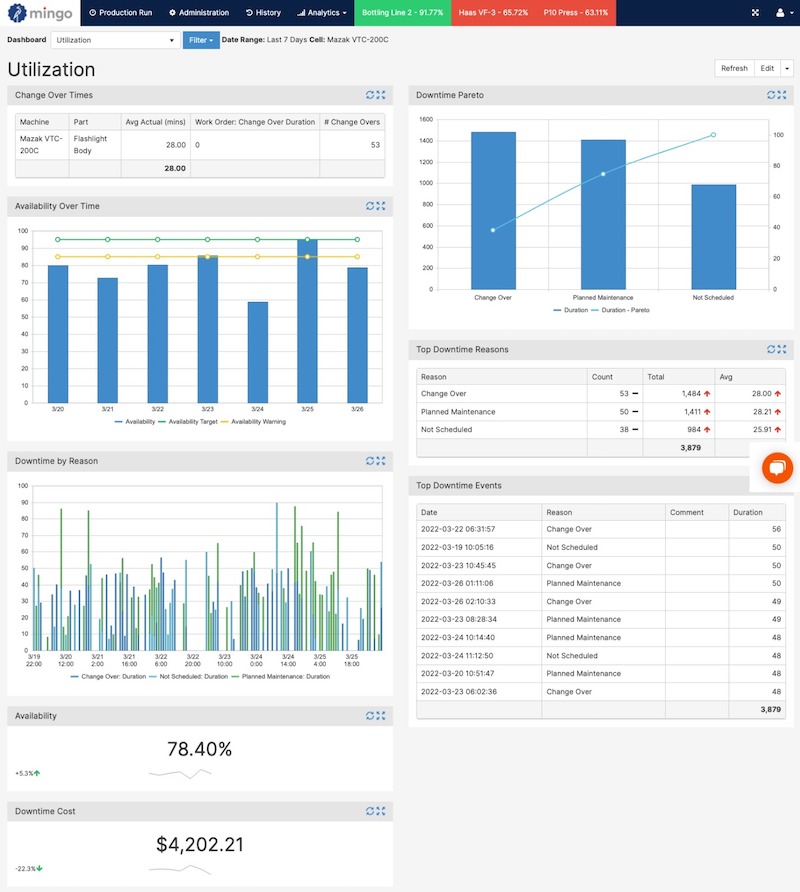

Collecting data is a wonderful thing but how do you use and make sense of it? This is where manufacturing analytics excels.

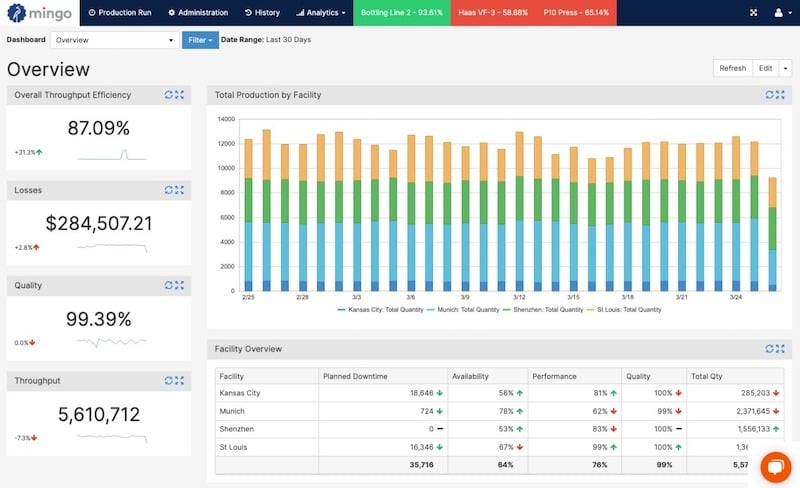

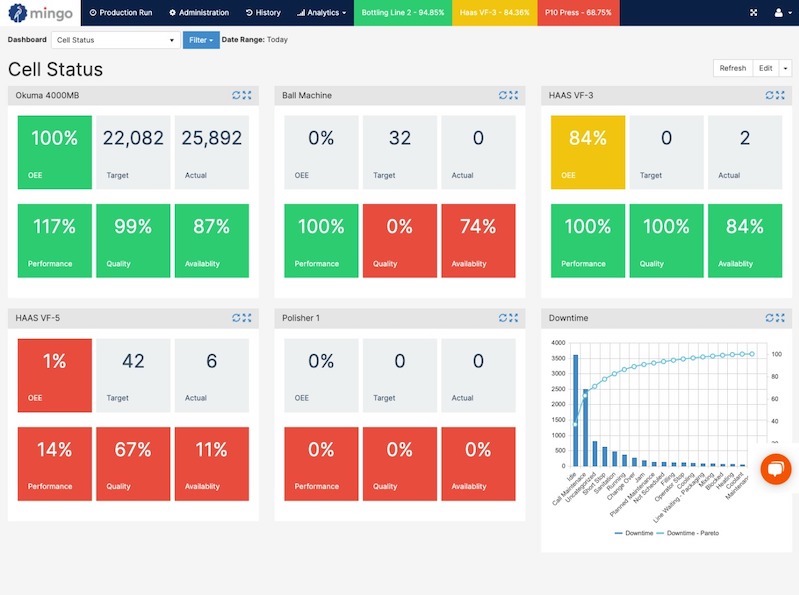

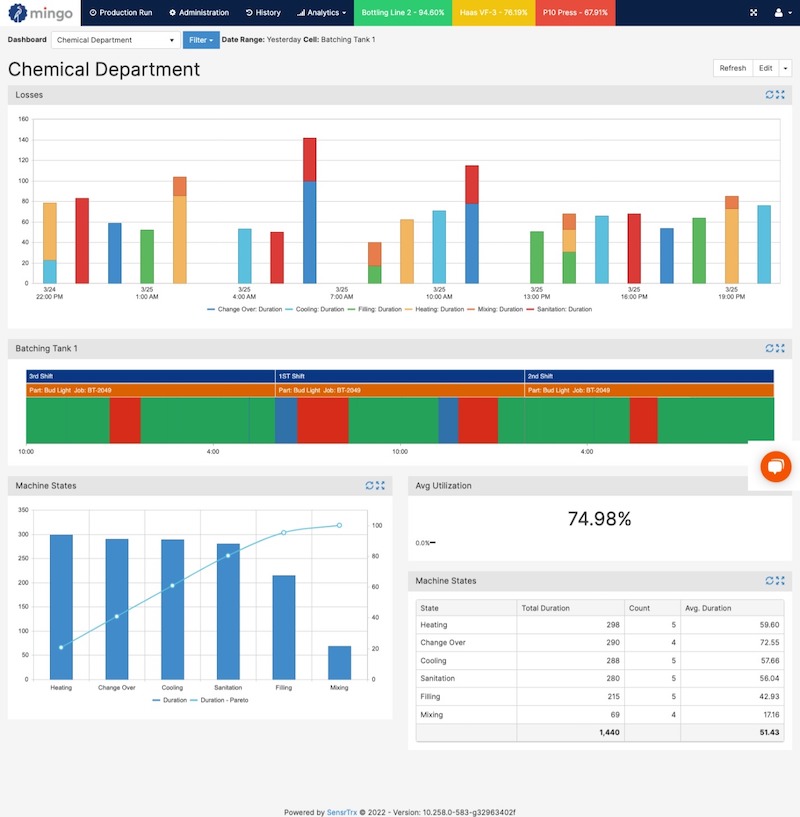

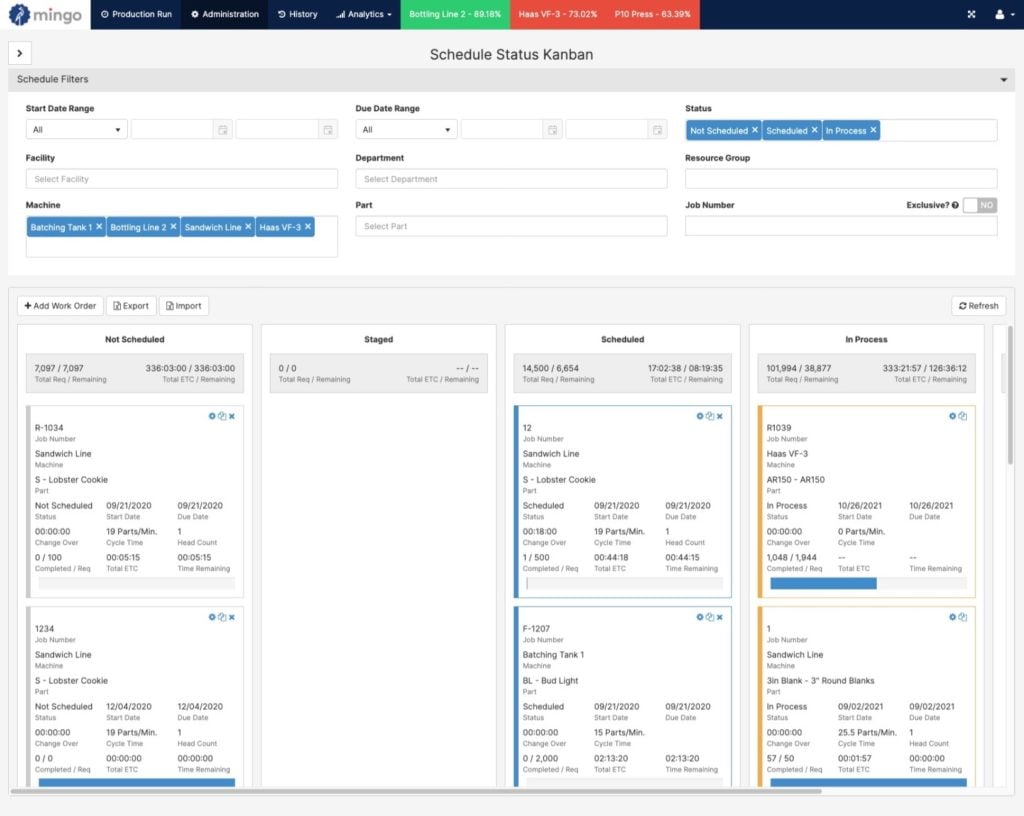

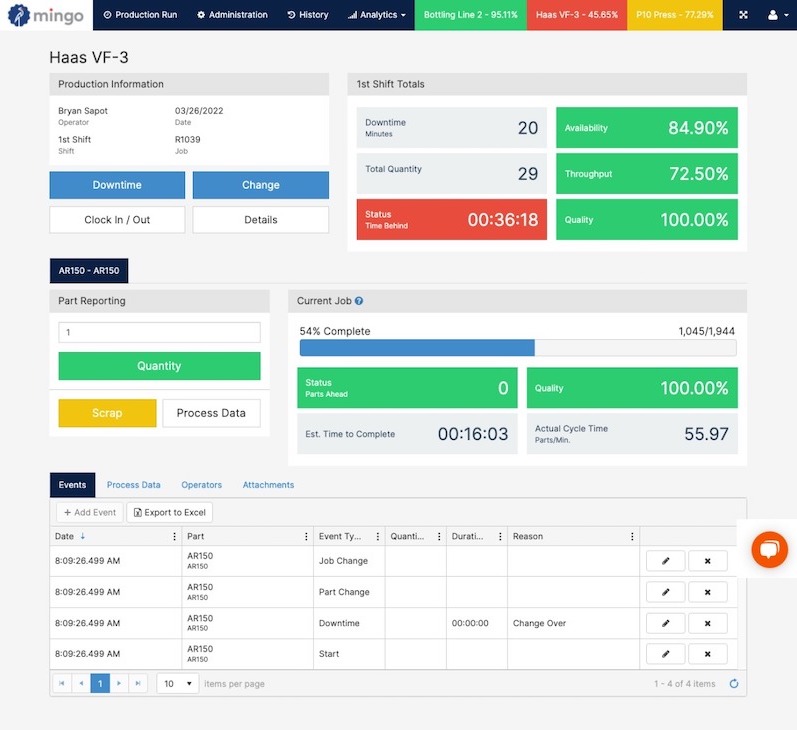

Massive amounts of data can be consolidated and summarized into easy-to-understand metrics, in real-time. The metrics are combined into standard dashboard components to help you understand what is happening in the shop. The dashboards provide access to data by role so users only see what is important to them and don’t get distracted by a lot of noise.

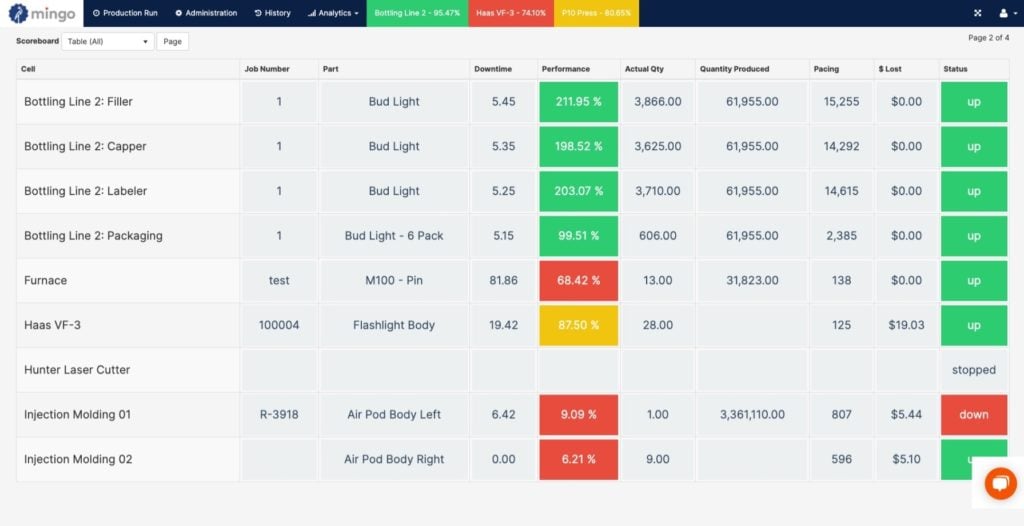

Scoreboards can be displayed in the shop so everyone can see how a cell, machine, or the entire plant is performing.