One Mingo customer has a mix of woodworking machines on their shop floor, used in creating renowned architectural mill and casework. Their company culture and market audience put a premium on sustainability, quality, and safety. Any changes they implement can impact the quality of their product so it was important for them to gather and measure the right data in their performance and quality analytics without distracting their people from the job on the floor.

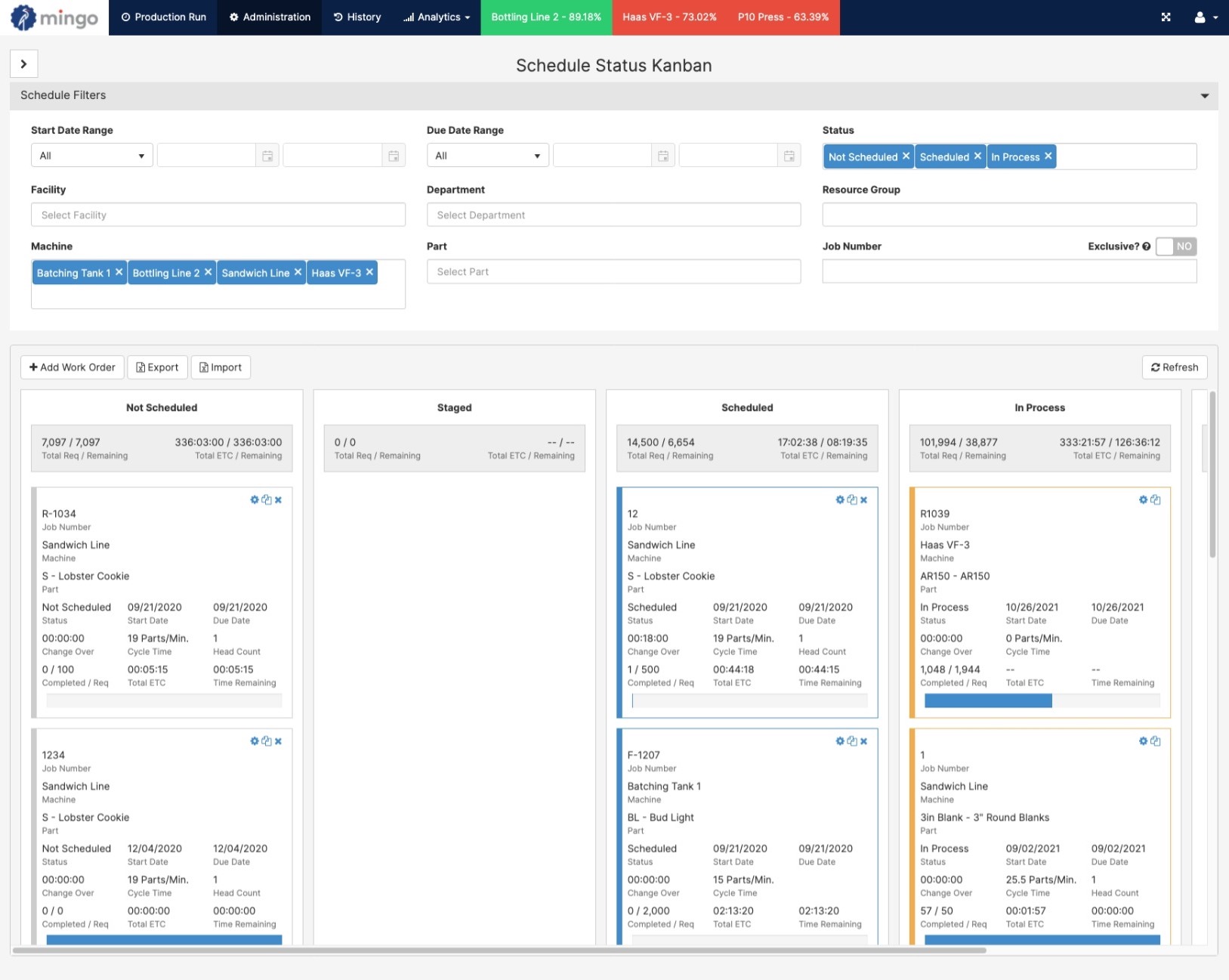

This type of wood manufacturing has a heavy manpower requirement since operators are handloading wood to be cut, planed, sanded, and finished by machines all day. Efforts to increase capacity and throughput have to start with their employees. This meant downtimes and cycle times needed to take the operator’s actions into context.

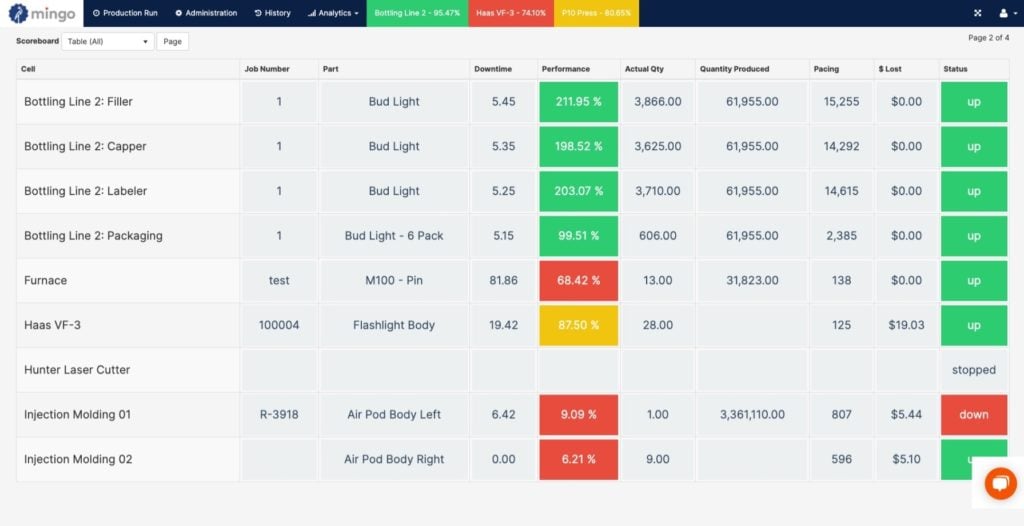

Mingo was evaluated in a side-by-side comparison with another vendor’s solution. Our customer liked that Mingo gathered data directly from their machine’s PLCs then augmented that data with operator input. With Mingo, they developed a reliable metric based on how their operators actually used the machines.

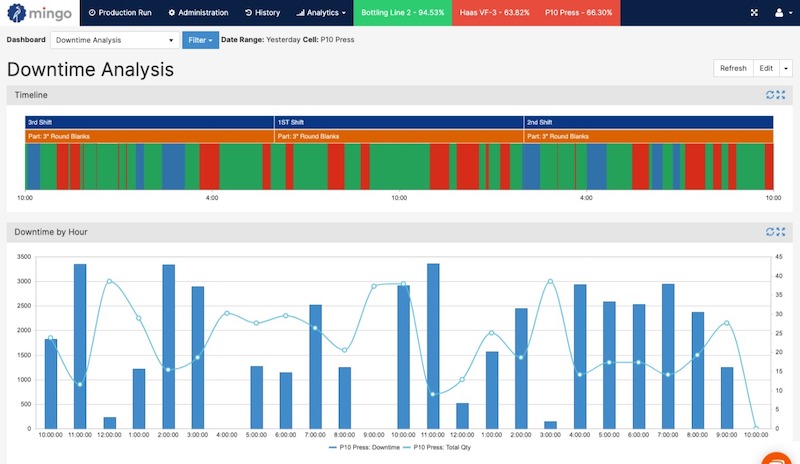

Shortstops and operator data can be input manually giving management a bird’s eye view of what it really takes to make a quality product on the mill floor, developing a clearer picture of their production process, cycle times, and performance. Now they get an honest picture of their performance and quality counts, two factors that when multiplied with availability make up their Overall Equipment Efficiency (OEE) numbers.

Those numbers are steadily improving, showing exactly what their people can do when they have the right data.