“I’ve been working with data and solving problems for the last 8 years, but never had anything in a place like Mingo,” Matt said. “Having Mingo started something we didn’t know before; all of the problems we thought were small problems actually weren’t.”

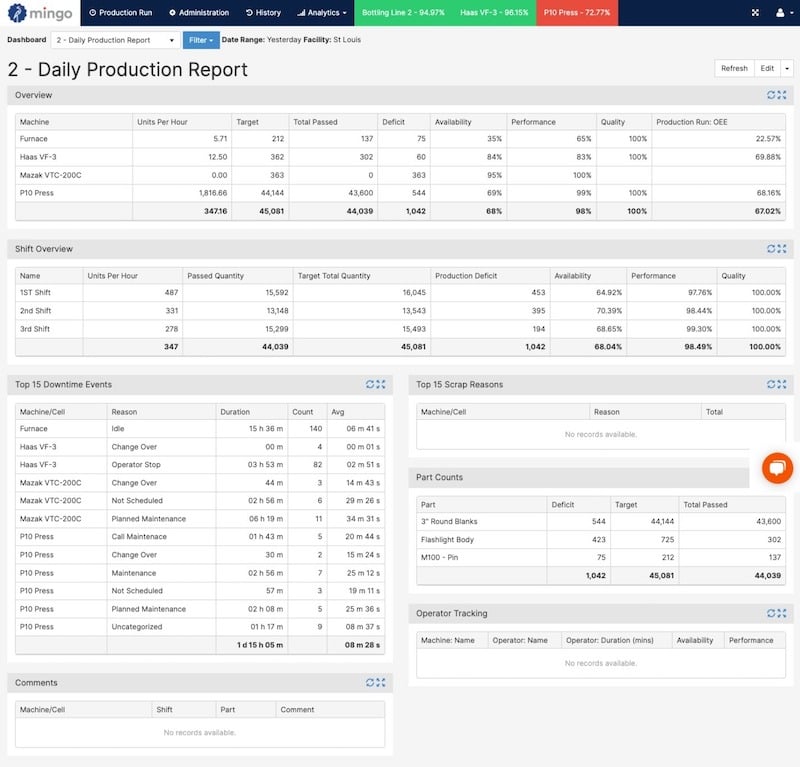

With real-time, tangible data, Matt and his team were able to implement corrective action to fix the problems affecting production, monitor the actions taken using alerts, and use the data going forward to monitor the effectiveness of those changes. Alerts helped H&T Waterbury monitor the effectiveness of changes made.

“The alerts we have are fantastic and have helped us tremendously over the past few months,” he said.

For the longest time, there was a problem with one of the machines that they just couldn’t figure out how to solve. While they’ve since solved the problem, which turned out to be a simple solution, alerts and manufacturing insights emails helped to solve it.

“We would monitor on Mingo to find out if the things we were doing were actually working, and it helped me not wake up at 2 in the morning to find out if the machine is running or not. I’d know of any problems before I went to bed.”

The data helps H&T know where they stand.

“What gets tracked, gets improved and now we have a much better understanding of our stoppages and the frequency of stoppages.”

As manufacturers know, improvement never stops, but as H&T learned, data can help to increase efficiency, reduce scrap, increase output, and eliminate micro stoppages and downtime on the floor.

“When you have a data-driven approach, you tend to work better as a team, too, because it’s fact and not opinion,” Matt added.

“Mingo was the simplest and most effective, and I would highly recommend it to anyone who asks,” he said and added, “You’d be surprised what the little bits add up to – big stoppages and lots of scrap.”