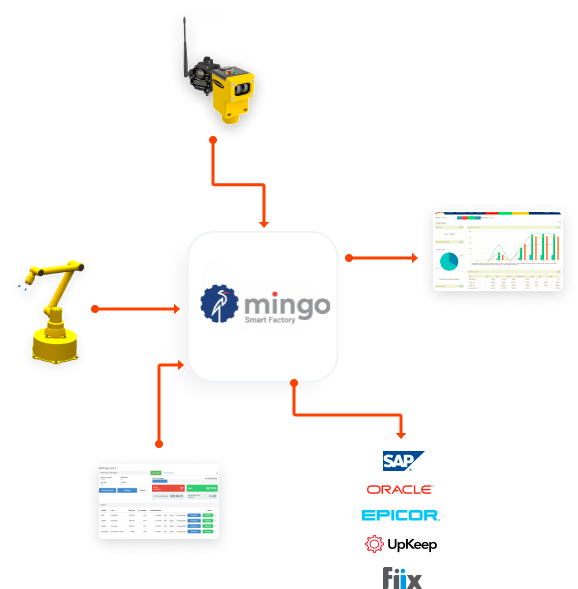

Connectivity is simple and straightforward. When you schedule a call with a member of our team to learn more about manufacturing analytics, we will ask a series of questions about your machines to help determine the best method of connectivity, and determine from there, the next steps that need to be taken. Most of the time, manufacturers already have the equipment necessary to connect to the software. It’s that easy! There are three ways we connect your machines to the software:

- Hardware to connect existing controllers or PLCs

- Sensors or wireless nodes to retrofit machines to collect data

- In areas with no machines, an operator can provide data to PC’s or tablets

During the sales process, we will help you figure out the best method to gather data from your machines, lines, or department. We have a variety of solutions to connect to all kinds of equipment. Don’t worry – this a simple process that doesn’t take long. The entire implementation process can take less than 1 day.